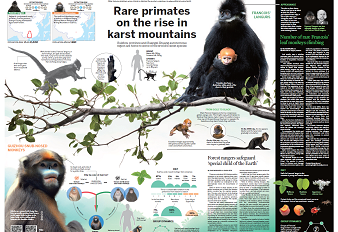

Baseball production swings big in Dushan county

The leather that covers a baseball is hand-sewn by residents in Dushan county, Guizhou province, in June. [Photo by Wei Zongbin/For China Daily]

Quality control is of utmost importance when weighing in on world-class balls

At the workshop of Dushan Runyang Sports Equipment Co in Dushan county, Guizhou province, a scale machine is used to strictly control the weight of each baseball the factory manufactures-between 142 and 147 grams.

Here, more than 10,000 baseballs roll off the production line every day and are exported to Europe and the United States.

Li Guangxiu, 67, a villager in Dushan county, has finished her work at a tea-making plant and returned home. She washes her hands and starts to watch TV while sewing the outside leather covers for a baseball.

"Sewing a baseball is to tie a shoelace on the ball," said Li, who has never played the sport and has barely watched it on TV.

More than 3,000 people in Dushan and four other counties in the region have been working in the production of baseballs, contributing to the growth of the local economy, said Shi Jinfen, a worker at the Runyang factory where she earns a monthly salary of about 5,000 yuan ($785) in the peak season while the sum is between 2,000 to 3,000 yuan during the rest of the year.

"To make one baseball, it takes seven steps, including making the cork center, wrapping it with leather and sewing the stitches by hand," said Shi.

Lu Zhidai, a villager in Dushan, said it took her 15 days to learn the craft at the factory. After passing a test, she can supply 20 baseballs a day that can sell for 1.65 yuan per ball to the factory.

To make a high-quality baseball, quality control is crucial.

"Customers have strict requirements for the weight of the ball. A small deviation can have a big influence on its trajectory and speed," said Wu Jili, a quality inspector at the company.

Nine out of 10 baseballs Runyang produces are exported to the US, and the rest to the European market and Japan. The total number of exports from Runyang amounts to about 50 percent of China's total baseball exports.

Geography makes Dushan an important link between inland Guizhou and major coastal ports in Guangdong province and the Guangxi Zhuang autonomous region. Products can be transported to ports in one day.

According to Jiang Shaohong, the company's production director, the factory has grown from a small workshop to a complete baseball production line that employs more than 200 people.

The production line, although not complicated, requires manufacturing facilities and equipment that are self-developed to achieve manufacturing efficiency. But most importantly, the skills of employees have served as the key to the success of the factory.

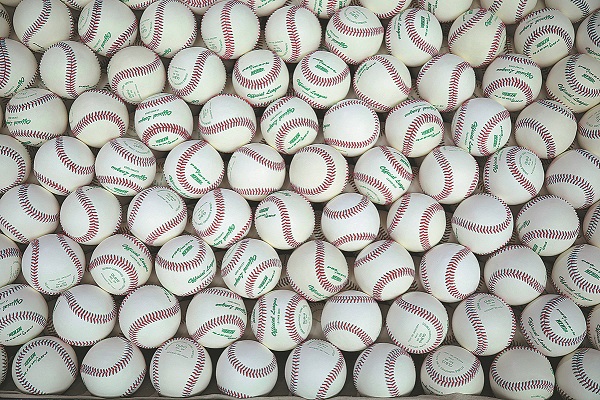

A view of baseballs produced in Dushan county, which are gaining popularity in Europe and the United States. [Photo by Wei Zongbin/For China Daily]

"Making a baseball is a labor-intensive process. The quality of baseballs depends more on the people who make them," said the director.

Since the beginning of this year, the company has collected orders for more than 5 million baseballs, with production plans scheduled in the first half.

The factory produced 3.8 million baseballs last year, generating a production value exceeding 27 million yuan.

Runyang's parent company is headquartered in Dongguan, Guangdong province, a manufacturer and exporter of baseballs for about two decades.

Its business model is to outsource rubber, leather wrappings and strings to farmers in the villages. The farmers, after training, are given a sewing machine at home to help them stitch the leather.

The local government in Dushan has issued supportive policies to facilitate the manufacturing businesses, including tax reductions in the first two years, and halving the taxation in the following three years for the plant.

The measures have echoed the provincial policies in developing industries. In January, the provincial government issued policies to cultivate 11 key development centers in the province. Guizhou has planned 500 industrial projects, aiming to attract investments of 280.6 billion yuan.

Since the outbreak of the COVID-19 pandemic, the Runyang factory has been on a rollercoaster ride, said the plant's production director Jiang. For nearly six months in 2020, the factory had not received any orders from overseas markets. To keep the factory running, many workers have been dispatched to re-examine the quality of each baseball. If any minor flaws were found, the baseballs were sent back for further quality repairs. It was a relief when in August, orders from the US returned and the factory resumed production.

The baseball business has been booming also in part as a result of the rising domestic baseball-playing as a niche sport.

By 2019, the baseball-playing population in China was about 41 million, with active players at 21 million, mainly located in first-tier cities including Beijing, Shanghai and Guangzhou, according to the 2019 China Baseball Population White Paper released by Major League Baseball China.

According to the report, adult baseball players are mainly middle-income earners, with 86.9 percent taking a college education and 82.1 percent with a monthly income above 8,000 yuan.

京ICP备13028878号-8

Overview

Overview Guiyang

Guiyang Guian New Area

Guian New Area Liupanshui

Liupanshui Anshun

Anshun Qianxinan

Qianxinan Qiandongnan

Qiandongnan Qiannan

Qiannan Zunyi

Zunyi Tongren

Tongren Bijie

Bijie Guizhou fosters cross-cultural bonds in Europe

Guizhou fosters cross-cultural bonds in Europe 18th Guizhou Tourism Industry Development Conference

18th Guizhou Tourism Industry Development Conference  Discover natural beauty in Qiannan, Guizhou

Discover natural beauty in Qiannan, Guizhou